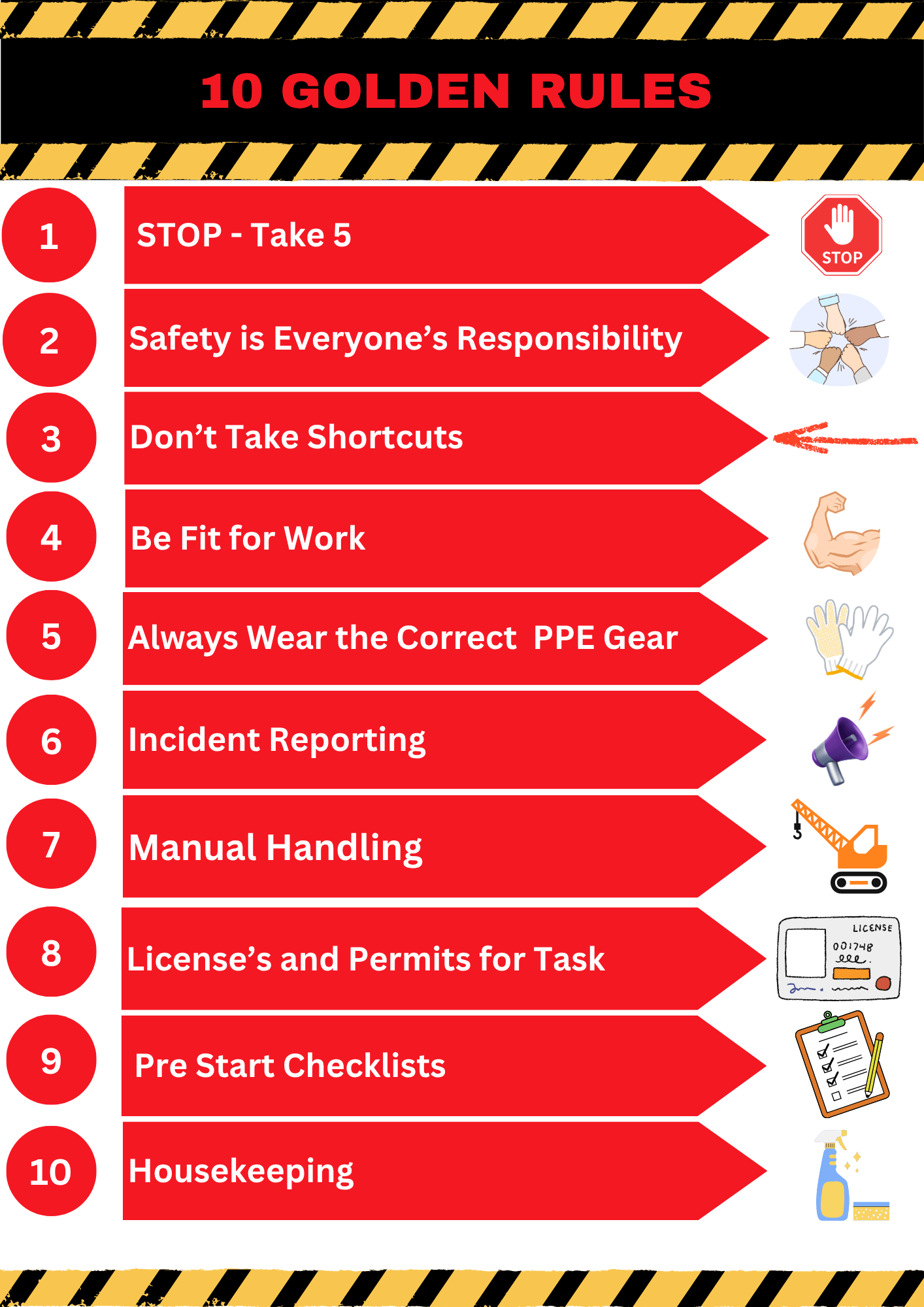

Before starting any task remember to STOP – Take 5

Maintaining a safe environment is not just the duty of safety professionals or management, it requires active participation from everyone.

Legal & Ethical Duty – Companies have legal obligations to ensure safety, but employees also have an ethical duty to protect themselves and others.

Taking shortcuts often leads to unforeseen problems and a reduced quality of work or experience.

While shortcuts might seem appealing for their speed, they frequently compromise thoroughness and can create bad habits and safety hazards.

Following the rules ensures consistency, quality, and protection for everyone involved. Whether it’s workplace safety, ethical decision-making, or even daily routines, doing things the right way sets a strong foundation for success. Staying vigilant and holding ourselves accountable makes a big difference. Keep leading by example!

Being “Fit for Work” means ensuring that you are physically, mentally, and emotionally capable of performing your job safely and effectively. It involves several key factors:

If you need help with any of the above, or just need to talk to someone, please contact Mates In Construction.

Make sure you have all the correct PPE gear require for the Assignment, and that it is damage free. Replace any worn or damaged PPE gear by contacting Building Recruitment Staff. PPE includes but is not limited to:

Reporting unsafe acts, events, and conditions is crucial for maintaining a safe work environment. It helps prevent accidents, ensures compliance with safety regulations, and fosters a culture of accountability.

Encourage a Safety Culture – Building Recruitment promotes open communication so to ensure everyone feels comfortable reporting hazards.

Manual handling in construction refers to the transporting or supporting of a load by hand or bodily force. It’s a common source of injuries in the industry, often leading to back strain, muscle strains, and other musculoskeletal disorders, one out of 5 people call in sick every day due to back injuries.

It’s important to remember your Safe Manual Handling training as it’s a crucial part in preventing back injuries:

Having the correct license / permit is essential for legal compliance and safety. In New Zealand, different types of licenses are required depending on the activity, such as driving, operating machinery, or running a business.

Licenses include but are not limited to:

Prestart Checklists are essential to ensuring the machinery or equipment you are about to use are safe and ready. A pre-start checklist is a systematic inspection conducted on equipment, vehicles, or tools before they are used, ensuring safety and preventing potential issues. It involves checking various aspects, including mechanical systems, electrical systems, fluid levels, and safety features, to identify and address any defects or hazards.

General Checks:

Examples of Specific Checks (Depending on Equipment)

Check out the HazardCo App for Checklists or contact Building Recruitment staff for assistance.

Good housekeeping is a great way to keep your workplace safe, and a tidy workspace shows that health and Safety is a Priority for you, your colleagues and the Company. Having a clean workspace saves injuries, time and money for you and the Company.

Benefits of Good Housekeeping:

Make housekeeping a good habit: